Sean C. Morgan

Of The New Era

Sweet Home’s new water treatement provider, OMI, Inc., has successfully automated the city’s water treatment plant and achieved what had been previously thought impossible, meeting requirements for chlorine contact time 16 times in two months.

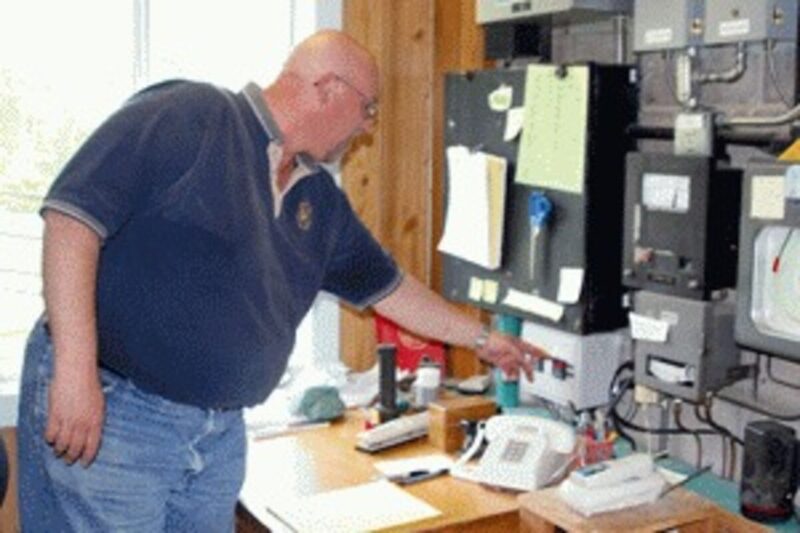

“We’ve automated that old thing that nobody said could be done,” OMI plant manager Doug Atkinson said. OMI installed small programmable logic controllers.

“I’m very happy and pleased with how it’s going,” Public Works Director Mike Adams said. “The process is running slower for longer periods of time. It’s allowed us to meet contact time basically eight days a month. It’s been a positive thing.”

In the late 1990s, the U.S. Environmental Protection Agency lengthened the required chlorine contact time for city water prior to reaching the first house.

With the short distance from the plant to the first house on Ninth Avenue, city officials have told The New Era previously that those chlorine contact times could not be achieved.

The city’s water continues to meet the standard set before the rule change, but because it has not been able to meet the new standard, every quarter, the city must mail out a form informing its users that its water does not meet that standard.

There had been some debate about among staff members how and whether the plant could be automated, Adams said, some insisting that it could not be done.

The logic controllers track changing pH levels, turbidity and chemical levels as well as how fast the plant makes water. If those levels go outside preset parameters, then they shut down the plant and alert an OMI employee.

OMI has been operating the city’s water and wastewater treatment plants under a contract since December.

With automation, OMI has been able to slow down water production and run the plan 24 hours a day, Atkinson said. The automation went on line two months ago. Since then, OMI has achieved the contact time requirement on 16 days.

The quarterly notice will continue though, Atkinson said. “We’re not going to meet it enough to prevent that.”

The new regulation has been one of the primary reasons for the city building a new water treatment plant. Also, officials have said the plant was built in 1937, and is deteriorating.

Even on days when OMI does not meet the standard, it is much closer to the contact time requirement than in the past, Atkinson said. The water quality has improved.

Before automation, the plant produced about 2,000 gallons per minute over a period of about nine hours, Atkinson said. The plant will do much more, but that’s the maximum speed allowed by the state. The plant ran 10-hour daily shifts seven days a week, but each day it would take about 45 minutes to get the plant started.

“If we can make this thing run 24 hours a day at 1,000 gallons a minute, number one, we’re going to make more water,” Atkinson said of OMI’s rationale for automating. “And there’s a possibility we’ll make some CTs (contact times) in there, which we’ve been able to do.”

Contact times are measured as a percentage, Atkinson said. At 2,000 gallons per minute, the plant made 43 percent of the requirement. At 1,000 gallons per minute, it typically does not reach less than 80 percent of the requirement. Even at 1,250 gallons per minute, the plant has met as high as 95 percent of the contact time requirement.

“I guess we’re really proud of that fact,” Atkinson said. “This has never been done before in this plant. When the CTs started coming in, we thought, this is really good. We’re making really good water in an old, antique plant. We’re pretty proud of that.”

From the time the plant would shut down each day and start up again the next day, the reservoirs would be down about 2.5 feet at the 10th Avenue site, which has a depth of 13 feet when full, Atkinson said. That’s about 1 million gallons of water per day.

By running all day, “we keep everything full now,” Atkinson said. Water quality is better, and that’s most important. But keeping the reservoirs full is important for fighting fires. A major fire can drop the reservoir on 10th by four or five feet. “It makes us nervous when we get down to four or five feet.”

At 1,250 gallons per minute, the plant can produce 1.8 million gallons per day, enough to meet the highest demand days during the summer.

“We tried running it a few days at 1,250,” Atkinson said. “Heck, the reservoirs got too full. We had to slow it down.”

The automation came at no expense to the city, Atkinson said. It wasn’t part of OMI’s contractual obligation.

OMI has more resources than the city does, Atkinson said. The company can pull resources and expertise from other communities. That’s how it got the automation done. An employee from another city actually installed the logic controllers.

“They were making good water, I have no doubt,” Atkinson said. “They just didn’t have the technical resources.”

OMI is altering the wastewater treatment plant as part of its contract though, Atkinson said. OMI is installing a sodium hypochloride system to replace gaseous chlorine in the wastewater treatment process.

Sodium hypochloride is a chemical found in bleach, Atkinson said. This system uses it in higher concentrations.

Using gaseous chlorine is highly dangerous, Atkinson said. Reducing it improves safety for the community and employees. A legislative bill will require wastewater plants to switch away from gaseous chloride soon anyway.

The city’s new water plant also will do away with gaseous chlorine in the treatment process and switch to sodium hypochlorite.

The changeover at the wastewater plant is about 95 percent complete, Atkinson said, representing about $20,000 in savings to the city between the two improvements.

OMI plans on being in Sweet Home for a long time, Atkinson said. “That’s part of our job, to come up with innovative ideas and solutions that won’t cost an arm and a leg.”

Next up, he said, people have been complaining about an odor problem from the wastewater plant. OMI will go to work on that and a couple of other projects.

“We know it’s a concern, and we’re not taking it lightly,” Atkinson said.